Why tungsten Flux Can Be Used in the Carbon and Sulfur Analyzer as Additive

- Details

- Category: Tungsten’s News

- Published on Tuesday, 14 September 2021 10:09

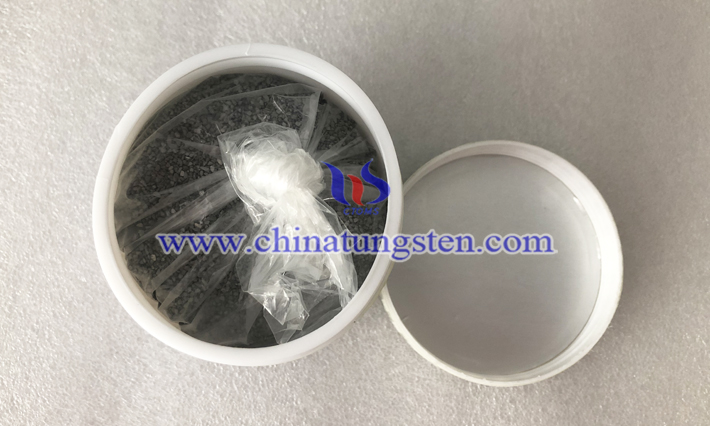

Tungsten flux is a kind of coarse particle made by breaking tungsten bars instead of sintered tungsten powder with purity of over 99.9%. There are others name for it, such as tungsten accelerator, tungsten chip accelerator, tungsten particles and tungsten granule.

Owing to its unique physical and chemical properties, it is widely used in many fields, for example, it is very suitable as a catalyst in a carbon and sulfur analyzer, used as a filler for shielding materials or used in radiation protection doors and baffles. Meanwhile, it is also suitable as a counterweight filler.

Why tungsten flux is used as the flux during the combustion process of high frequency furnace in the analysis of infrared carbon and sulfur?

With a melting point of 3380°C, tungsten is the most difficult metal to melt. However, the metal is easy to oxide. Tungsten begins to oxidize and emit a lot of heat when oxygen is passed through at 650°C. The infrared carbon-sulfur analyzer has the characteristics of high instantaneous heating value and fast reaction speed, so tungsten particles are needed as additive.

Some people may consider this product only as flux, actually, it can be used as additive. In the infrared carbon-sulfur analyzer, tungsten granule also generates heat, adjusts the acidity and alkalinity of the medium, stirs, catalyzes, stabilizes combustion, and anti-interference. Its roles are important and multiple.

With the help of the flux, the accuracy of the measurement value tested by carbon and sulfur analyzers can be effectively improved. The carbon and sulfur analyzer can quickly and accurately analyze the carbon and sulfur content in solid and fluid materials such as carbon steel, high, medium and low alloy steel, pig iron, gray cast iron, ductile iron, alloy cast iron, various iron alloys, ferrosilicon, ferromanganese, nickel iron, lithium iron, ferrochromium, rare earth metals, and coke, coal, slag, catalyst, ores and so one.

As a professional manufacturer over two decades, Chinatungsten Online provides high-purity tungsten granule as well as many other parts. Please contact us if you have any inquiry.

- Next >

Link to this article:Why Tungsten Flux Can Be Used in the Carbon and Sulfur Analyzer as Additive

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^