Bayerische Metallwerke Patents 3D Printing tungsten Alloy Production Technology

- Details

- Category: Tungsten’s News

- Published on Saturday, 31 July 2021 19:25

The Germany-based metal processing company Bayerische Metallwerke GmbH, a subsidiary of Wolfram Industrie, has developed and patented a new tungsten alloy production technology for 3D printing.

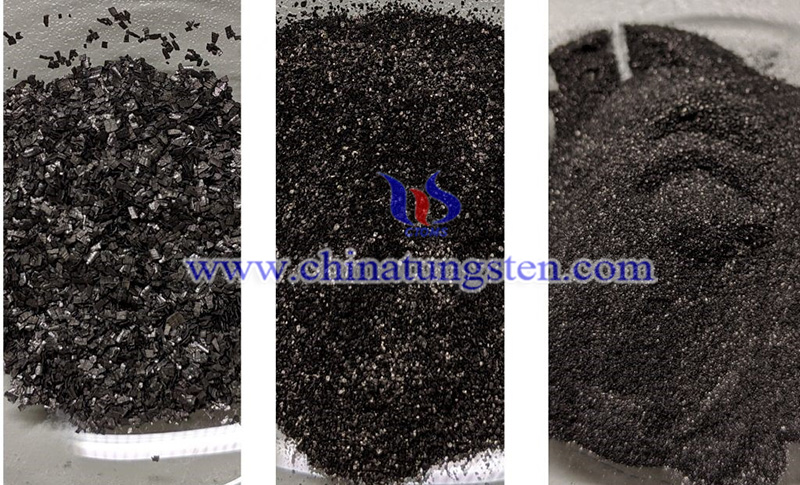

The special feature of this process is that it can produce high-concentration tungsten pre-alloy mixtures (WNiFe and WNiCu) in powder form, enabling these materials to be used in 3D-printing and coating processes. Supported by the two-year development phase, the company believes that its new process will pave the way for more complex part geometries made of tungsten, providing new options for applications such as tool manufacturing and 3D-printing radiation shielding.

"The special thing about our tungsten-nickel-iron alloy is that we obtain it as a pre-alloyed powder," explains Dr. Hany Gobran, R&D manager at Bayerische Metallwerke. "This is suitable as a starting product for 3D printing and coating processes."

Tungsten alloy is known for its excellent corrosion resistance and high thermal conductivity, making it an ideal choice for cold Die Casting of aluminum parts.

Heavy metals are also very dense, with a density of 19.3 g/cm³. Tungsten has a density comparable to gold and is widely used for alpha and gamma radiation shielding in tool manufacturing and healthcare.

Nabil Gdoura, R&D engineer at Bayerische Metallwerke, said: “Tungsten has become the material of choice in the field of cast aluminum due to its resistance to corrosion and erosion by molten metals and its excellent thermal conductivity."

"The extremely high density of its pure form also makes it a good substitute for harmful lead. For example, lead is still used for radiation shielding in medicine."

Unfortunately, the melting point of tungsten is also the highest of all chemical elements (3,400°C), and its Mohs hardness is 7.5, so it is difficult to process.

Therefore, tungsten parts with more complex geometries (such as curves and holes) are usually made of hot work tool steel only because of its ease of use and 3D

According to Bayerische Metallwerke, to date, all commercially available tungsten 3D printing alloys have been produced with relatively high concentrations of iron and nickel, usually without any pre-alloying. Because the melting point of these metals is significantly lower than that of tungsten, high-temperature additive manufacturing processes such as powder bed melting often result in uncontrollable evaporation.

The new Bayerische Metallwerke process addresses this problem by pre-alloying the powder mixture before processing. By combining all three elements as a multiphase material in each powder particle, the composition and distribution of the final alloy can be very tightly controlled. Therefore, metals can be processed at high temperatures without losing any iron, nickel, or copper.

The company stated that its new process is capable of producing alloys containing 80%-98.5% (by weight) tungsten, 0.1%-15% nickel, and 0.1%-10% iron and/or copper, depending on the desired application. The density of the alloy material is 17 – 18.8 g/cm3, which is very suitable for traditional use cases of tungsten in aluminum casting, tool manufacturing and radiation shielding. Additionally, the patented process can also determine the flow behavior and particle size of powder particles.

"The higher the proportion of tungsten in the final product, the more resistant it is to molten aluminum and the better the thermal conductivity,” Gobran concluded. "On the other hand, if good ductility and machinability play a greater role, the proportion of tungsten in the alloy can be reduced accordingly. Therefore, the composition can always be adapted to the corresponding complexity of the specific application and shape."

The powder production sector is critical to the success of industrial additive manufacturing. Earlier this year, Pyrogenesis, an expert in plasma atomization technology, announced the successful test of its additive manufacturing NexGen powder production line. After making a strategic decision to postpone commercial production, the Montreal-based company was able to implement improvements and has now tested batch-to-batch consistency on its production line.

Moreover, Canadian mining and metals company Rio Tinto developed a new type of steel 3D printing powder using water atomization technology recently. Although it is generally believed that only high-cost gas and plasma atomizers can produce industrial-grade powder, the company's new steel powder shows that water atomization is a more economical.

- < Prev

- Next >

Link to this article:Bayerische Metallwerke Patents 3D Printing Tungsten Alloy Production Technology

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^