tungsten steel plates produce high-end tungsten steel plates for the automotive industry, and PTJ tungsten steel processing produces high-end tungsten steel plates for the automotive equipment industry.

The development of automation in the automotive industry puts forward higher requirements for the performance of tools used in precision machining. The core working components used by automated welding equipment and industrial robots in the automotive equipment industry require wear resistance to meet long-lasting precision service life, which requires higher quality The tungsten steel material to meet the performance. As an industrial tooth, tungsten steel has good physical properties and is suitable for the processing of metal parts in the automotive equipment industry, and is especially suitable for the continuous operation of automated mechanical parts.

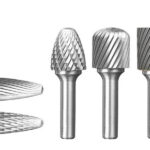

As a super-hard tool material, tungsten steel plate is a relatively widely used size and shape of tungsten steel material. It has different performance requirements according to the specific use of mechanical industry production. It is used for metal material cutting, wear-resistant parts, and progressive molds. The use of stamping dies, drawing dies, powder dies, metal cold rolling, 3D glass hot bending, etc., have different applicability to the material properties of tungsten steel plates and tungsten steel blocks. PTJ Cemented Carbide Production Co., Ltd. provides customized processing of non-standard sizes according to the differentiation according to the needs of customers and friends. Customized sizes according to the requirements of automobile industry machinery and equipment are:

1.200-200-18.5

2.125-125-12

3.105-105-18

PTJ tungsten steel sheet production and processing can be customized for customers and friends, such as 200-200-13.5, 200-200-15, 200-200-20, 105-105-70 and other size specifications, according to the requirements of use for fine grinding processing, dimensional tolerances The requirements are met from ±0.01 to ±0.002. Other size specifications can also provide 210*130*12, 210*151*12, 200*136*10, 200*150*10, 210*120*40 and other customized production, the maximum size can meet the length and width 500mm*500mm, height The requirements can meet 70mm-80mm, and the finish after finishing can meet Ra0.2, Ra0.4, Ra0.8, etc.

Tungsten steel plates are customized for high-end automotive industry tungsten steel plates, and PTJ cemented carbide is specialized in tungsten steel processing. As a cutting tool or mold cavity, tungsten steel sheet can meet better performance and size processing. The physical parameters of commonly used tungsten steel plates for fine grinding alloy plates are as follows:

1. Co content: 6%-20%,

2. Density g/cm3: 13.1~14.8,

3. Hardness: HRA86.5-93.8,

4. Grain size: 0.2-1.6um,

5. Bending strength: 2800-5500MPa,

6. Elastic modulus GPa: 470-560.

Link to this article:Tungsten steel plate production high-end automotive industry tungsten steel plate block customization

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^