tungsten steel processing precision tungsten steel valve core tungsten steel valve sleeve tungsten steel valve head gasket, PTJ tungsten steel processing precision custom provides tungsten steel valve core, tungsten steel valve sleeve, tungsten steel valve head, tungsten steel valve cushion, tungsten steel valve stem, etc. Glue-filled mechanical seal slides with combined tungsten steel parts.

The improvement of the performance of tool materials continues to promote the sustainable development of the economy and society. The rapid development of the electronics industry puts forward the requirements of more long-lasting service life for the precision parts of the glue-filling machinery and equipment. For the cemented carbide parts, precision tungsten steel processing The tungsten steel valve sleeve and valve head made of cemented carbide spool have good performance. Glue-filling machinery is an automated machinery that specifically controls fluids and drips, coats, and encapsulates the liquid on the product surface or inside the product. Automatic integration requires high-precision, abrasion-resistant, and durable parts for the use of machinery and equipment. For life operations, the choice of cemented carbide parts processed by tungsten steel can meet the requirements well.

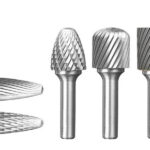

PTJ tungsten steel processing precision tungsten steel valve core, tungsten steel valve sleeve, tungsten steel valve head gasket, according to the requirements of the glue filling and glue control mechanical equipment drawings, the sliding combination production, its size specifications are:

1. Tungsten steel inlet valve core: Φ9-13*Φ3*M3-14-C0.3*R0.5*30,

2. Tungsten steel glue outlet valve core: Φ9-10*Φ4-3-15°*Φ3*M3-14-C0.3*R0.5*30,

3. Tungsten steel inlet valve head gasket: Φ12*Φ6-4.2-∠0.03-30°*R0.5*5,

4. Tungsten steel outlet valve head gasket: Φ12*Φ3-4.2-∠0.03-20°*R0.5*5,

5. Tungsten steel valve shaft: Φ29-4*ΦΦ26.7-2.7*Φ12-28.1*Φ5.5-24*Φ12-13.2*72.

This series of precision tungsten steel machined carbide valve core, valve sleeve, valve head gasket needs to be used in combination. The M3 thread is ground to meet the matching requirements, and the alignment tolerance meets the coaxiality requirement of 0.03, the roundness requirement of 0.02, and the inclination. The requirements are 0.03, the verticality is 0.03, the flatness is 0.02, and the finish is Ra0.2 to meet the overall compatibility of the glue filling and glue control machinery and equipment.

As the primary productive force, science and technology promote the continuous development of the economy and society. The mass industrial production of the automobile industry, the electronics industry, and the lighting industry puts forward new requirements for liquid glue control technology, as well as requirements for the performance and accuracy of glue control and glue filling equipment. Continuous improving. If a worker wants to do his job well, he must first sharpen his tools. The improvement of tool material performance is an effective way to improve the efficiency of mass industrial production. As a manufacturer of tungsten carbide processing precision tungsten steel parts and tungsten steel accessories, PTJ Cemented Carbide is committed to providing precision carbide custom tungsten steel processing for mechanical equipment.

Link to this article:Tungsten steel processing precision tungsten steel valve core tungsten steel valve sleeve tungsten steel valve head gasket

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^