The Antarctic Bear has also repeatedly reported on two-photon 3D printing technology, which is a 3D printing technology on the nanometer scale, which uses two-photon photolithography to print nano-scale structures. However, its biggest drawback is The printing speed is too slow. So, is there a way to increase its printing speed?

Hong Kong Wen Wei Po News: 3D printing technology has gradually become well-known after more than 20 years of development. People can quickly manufacture finished products by building digital models. Nano-level 3D printing technology belongs to a branch of 3D printing, and the printed products are usually small enough to be seen by the naked eye. No, but the complexity is no less than that of traditional 3D printing products, and the precision is also in the hundreds of nanometers. However, the existing nano-level 3D printing technology has long faced the two difficulties of slow printing speed and high cost, and it has not been able to achieve wider applications. .Recently, Chen Shiqi, associate professor of the Department of Mechanical and Automation Engineering, School of Engineering, The Chinese University of Hong Kong, and his team broke through the academic bottleneck and developed the “femtosecond projection two-photon lithography 3D printing” (FP-TPL) technology, which greatly increased the original printing speed. Increase by thousands to 10,000 times, and save costs in disguise, with a reduction of 98%.

Common 3D high-precision printing technology generally uses a two-photon polymerization system (TPP), which uses a laser string to write point by point, and then print layer by layer. 0.1mm3 per hour), even if it takes several days or even weeks to manufacture small devices. In addition, the laser light source has a life limit. Generally, each machine can only be used for about 20,000 hours. Long-term use has caused the high cost of TPP printing. .

The old trick is one year, the new trick is 10 hours

In order to overcome the difficulties of the existing technology, Chen Shiqi and his team have devoted themselves to research for 5 years, and cooperated with the U.S. Lawrence Livermore National Laboratory to develop the FP-TPL technology. The relevant research results have been published in October this year. Published in the academic journal Science. The new technology uses an innovative focusing method to project 1 million light points at the same time to form a light plane, reforming the laser 3D printing process into a whole plane writing, and the printing speed is greatly increased by thousands of times to 1 Ten thousand times. In the past technology used to scan a little time, the new technology can scan a whole plane and complete a layer of writing in femtoseconds.

FP-TPL technology increases the printing speed to 10 to 100mm3 per hour [Antarctic bear note: equivalent to an increase of 100-1000 times], and the printing cost is therefore greatly reduced to 1.5 US dollars per cubic millimeter, and the precision is also improved, up to 140 × 175 nm.

Chen Shiqi explained that nano-level printing technology is generally not used to print larger objects due to its high-precision requirements. He gave an example. For example, it may take nearly a year to print a 1 Hong Kong dollar using the traditional TPP method, but if you use FP- TPL technology can be shortened to less than 10 hours.

There is still a distance from industrial production

Regarding the future application of FP-TPL technology, Chen Shiqi said that due to cost constraints, FP-TPL is still a certain distance from large-scale industrial production, but Silicon Valley financing companies are already in contact with the team. In the field of micro 3D printing, he We are optimistic about using FP-TPL for experimental research in disciplines such as optics and biomedicine, and manufacturing experimental equipment including photonic crystals, nanorobots, biological scaffolds or metamaterials.

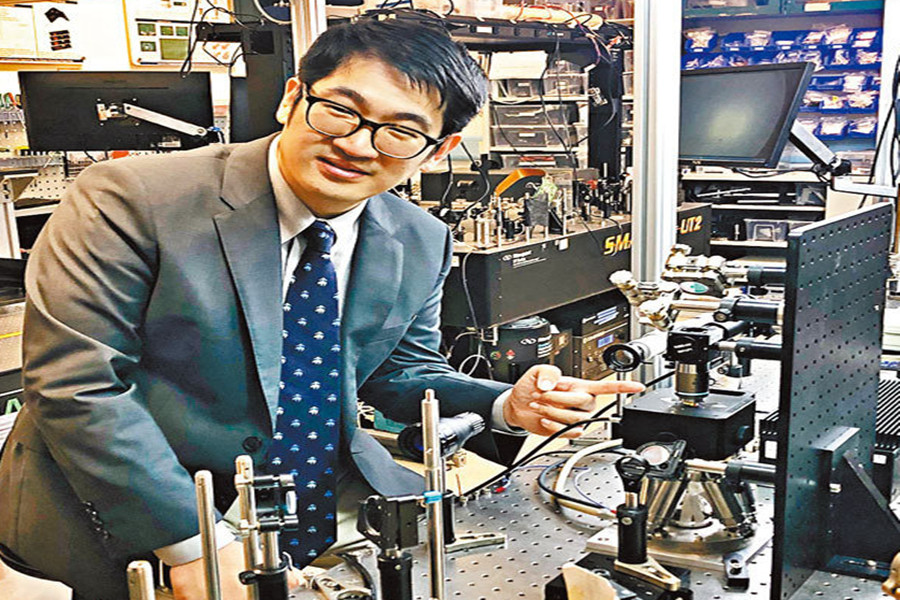

Chen Shiqi graduated from the Department of Mechanical Engineering of Tsinghua University in Taiwan, received a master’s degree and a doctorate degree from the Massachusetts Institute of Technology and Cambridge University, respectively, and did research at Harvard Medical School. He joined CUHK in 2011 and his main research scope includes nano 3D Printing, high-speed 3D imaging, etc. Last year, he won the U.S. R&D Global Top 100 Technology R&D Award for his research results on the “Digital Holographic Nano 3D Printer”.

The “Digital Holographic Nano-Builder” (Nano-Builder) developed by Professor Chen Shiqi from the Department of Mechanical and Automation Engineering, School of Engineering, The Chinese University of Hong Kong (CUHK), and his team has won the global R&D100 known as the “Oscar in Innovation and Technology” Recognized by the annual award, it was selected as one of the 100 most innovative inventions in the world in 2018. Nano-Builder can print complex and hair-like fine components in seconds, especially suitable for high-end nanotechnology, advanced materials, micro-stents and drugs Transmission technology research and development needs.

Nano-Builder adopts revolutionary digital holographic laser scanning and beam shaping technology, capable of high-speed (22.7 kHz) multi-focus scanning, breaking the limitations of traditional 3D printers with single focus and low precision, and at the same time achieving nano-level printing accuracy. The technology can scan randomly in a three-dimensional space, without scanning from the bottom to the top layer by layer, which goes beyond the elbow of space.

Multiple scanning focal points can be moved to any point in the printing space at the same speed. Even without the support of structure and materials, it can still print out complex overhanging structures, precise and detailed micro-finished products. Compared with the existing technology, the process does not need It wastes extra materials as support; and the total printing time is proportional to the solid volume of the structure, and has nothing to do with the complexity, which greatly improves the speed and accuracy of printing. Professor Chen Shiqi said that the fast and precise Nano-Builder is the most effective It is conducive to the development of various micro-scale scientific research devices (such as photonic crystals, micro-nano fluidic devices, simulated biological tissues and scaffolds, drug delivery tools, etc.) to assist researchers in making complex and sophisticated components, thereby revolutionizing nanotechnology and advanced materials And related technologies of medical tools.

Another major feature is its convenient system modular design and extensibility. Nano-Builder’s imaging module can be quickly replaced, providing advanced two-photon microscopy imaging functions, which are used in biological and medical imaging and other fields. In genetic research applications, Nano-Builder can accurately stimulate multiple neurons in the biological brain at the same time without harming the surrounding structures of neurons. It can be used for long-term research on brain neural circuits and specific functions, such as the sense of smell in mice or zebrafish. , Visual or cognitive functions, extending the advantages of 3D random scanning to medical or basic biological research tools.

Link to this article: New focusing method helps photon lithography 3D printing save 98% of costs

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

Link to this article:New focusing method helps photon lithography 3D printing save 98% of costs

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^