Scientists at the Technion-Israel Institute of Technology have developed an automated production line for 3D printing low-cost custom prostheses.

In the simplified design process of the team, the unaffected hand of the amputee was scanned first, the CAD software was used to cut it, and then it was directly converted into a printable STL file. Then, by clicking a button, the generated parts can be easily assembled into realistic limbs with advanced object gripping functions, thereby providing patients with a higher quality of life.

Promote the development of barrier-free prosthetics

Losing a hand will increase the degree of dependence on others and seriously affect the quality of life, but the cost of a general prosthesis is between US$3,000 and US$100,000. Moreover, the price of many amputees exceeds the price of custom equipment, especially considering that they usually require costly manual installations by trained professionals for optimal performance.

In addition to cost, prostheses suffer from other problems that lead to high matching rates, including their appearance, weight, grip, and lack of sensory feedback. The rejection of such patients can also lead to serious consequences, leading to joint and muscle degeneration, painful inflammation, and many other potentially serious complications.

At the same time, using 3D printing, it is now possible to reduce the assembly steps required to manufacture prostheses, while creating more complex designs, and many recent projects have successfully achieved this. However, the development of low-cost artificial limbs with consistent characteristics and fast enough to meet the demand is still a problem.

In order to increase production and reduce reliance on well-trained experts, Israeli scientists have therefore developed a digital design pipeline that can produce reasonably priced prostheses without manual intervention.

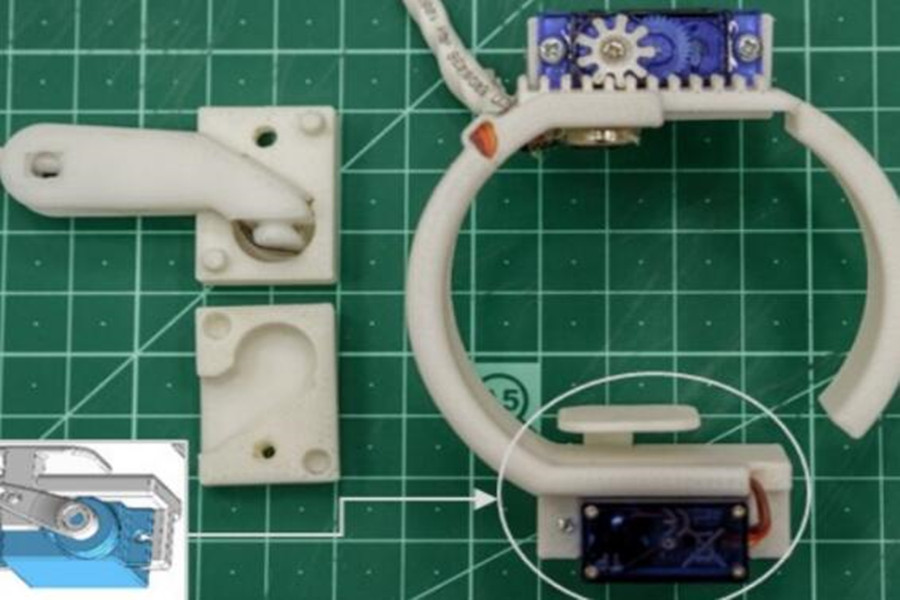

The team’s 3D printed hand has an embedded force sensor to enable it to have a sensing function.

The researcher’s production line basically consists of four steps: scanning, modeling, 3D printing and assembly. In the initial design stage, the appearance of the artificial limb can be customized according to the user’s preferences, and the patient can choose between physically powered hands and more advanced EMG-controlled devices.

After the restoration is completed, it will be automatically converted into an STL file and sent for printing. Although the scientists’ workflow still requires manual assembly of the final parts, they have found that the previous steps can be optimized to shorten the process, making the construction simple, fast, and user-friendly.

In order to make the setup as feasible as possible, the Israeli team even created a low-cost custom scanner based on the Intel RealSense camera for about $40. The prostheses found are not inferior, as they have been shown to be capable of pouring liquids and holding household items more than 50,000 times.

In other tests, the prosthesis showed the ability to adapt its gripping level to ultra-soft or rigid objects, and its motors would stop at different times according to the resistance level. Although the prosthesis has not yet been introduced to potential users, when the amputee saw it, they praised the weight and realistic appearance of the prosthesis, indicating that the patient’s rejection may be minimized.

In the end, the scientists concluded that by eliminating the need for expensive manual assembly, their 3D printing production line could significantly reduce the cost of prostheses for those in need.

Although 3D printed prostheses have been around for several years, the focus of the industry has recently shifted to making them more accessible to amputees.

For example, Partial Hand Solutions, a prosthetic manufacturer, used Formlabs’ new Form 1 3D printer in its production process, allowing it to produce 80 artificial fingers every day. Using the machine also allows the company to manufacture limbs that are both cheaper and better suited to the needs of patients.

Similarly, researchers at Lincoln University have developed a 3D printed sensor-operated prosthetic arm designed specifically for two-year-old children. In view of the growing growth of many children, the device has been constructed as an affordable alternative that is easier to obtain.

In other places, customized prostheses have been developed to meet the needs of patients suffering from various other injuries, and scientists have even gotten into the trouble of not being able to 3D print testicles. According to reports, South Korean men must pay more than US$715 for artificial gonads.

The researchers’ findings are detailed in their paper entitled “Scan-driven fully automated pipelines for personalized 3D printing low-cost prosthetic hands.” This research was co-authored by Yair Herbst, Shunit Polinsky, Anath Fischer, Yoav Medan, Ronit Schneor, Joshua Kahn and Alon Wolf.

Link to this article:Low-cost automatic 3D printing prosthetic production line

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

Link to this article:Low-cost automatic 3D printing prosthetic production line

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^