In the process of CNC turning, some thin-walled parts are often processed. When turning thin-walled workpieces, due to the poor rigidity of the workpiece, the deformation of thin-walled workpieces on CNC lathes is generally the following phenomena during the turning process.

- 1. Because of the thin wall of the workpiece, it is easy to deform under the action of clamping pressure. Thereby affecting the dimensional accuracy and shape accuracy of the workpiece. When using the three-jaw chuck as shown in Figure 1 to clamp the workpiece to process the inner hole, it will slightly become a triangle under the action of the clamping force, but a cylindrical hole is obtained after turning the hole. When the jaws are released and the workpiece is removed, the outer circle returns to a cylindrical shape due to the elastic recovery, while the inner hole becomes an arc-shaped triangle as shown in Figure 2. When measuring with an internal micrometer, the diameter D in all directions is equal.

- 2. Under the action of cutting force (especially radial cutting force), it is easy to produce vibration and deformation, which affect the dimensional accuracy, shape, position accuracy and surface roughness of the workpiece.

- 3. Because the workpiece is thin, the heat of cutting will cause thermal deformation of the workpiece, which makes it difficult to control the size of the workpiece. For metal thin-walled workpieces with large linear expansion coefficients, such as continuous semi-finished turning and finishing turning in one installation, the thermal deformation of the workpiece caused by the cutting heat will greatly affect its dimensional accuracy, and sometimes even make the workpiece Stuck on the fixture.

We know how deformed thin-walled workpieces are processed by CNC lathes, so what should we do about the deformation of thin-walled workpieces on CNC lathes? Several solutions are described below.

- 1. The workpiece is divided into rough parts. During the rough turning in the finishing turning stage, due to the larger cutting margin, the clamping force is slightly larger, and the deformation is correspondingly larger; during the finishing turning, the clamping force can be slightly smaller, and on the one hand, the clamping is deformed. On the other hand, it can also eliminate the deformation caused by excessive cutting force during rough turning.

- 2. When using geometric parameters to fine-turn thin-walled workpieces reasonably, the rigidity is required to be high, the wiper blade is not easy to be too long (usually 0.2-0.3mm), and the cutting edge should be sharp.

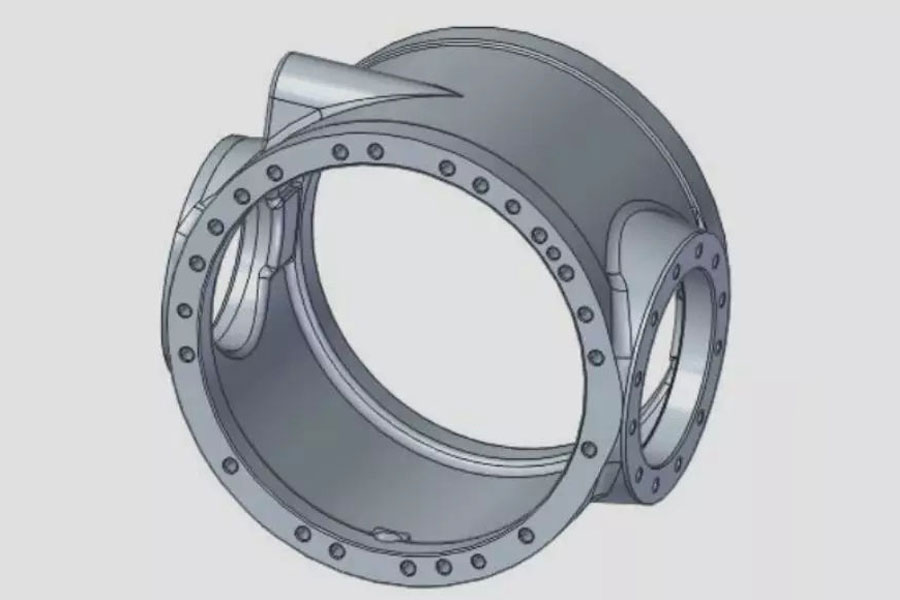

- 3. Increase the clamping contact surface as shown in Figure 3. Use a slit sleeve or some special soft jaws. The contact surface is enlarged, so that the clamping force is evenly distributed on the workpiece, so that the workpiece is not easily deformed during clamping.

- 4. Fully pouring the cutting fluid. By fully pouring the cutting fluid, reduce the cutting temperature and reduce the thermal deformation of the workpiece.

- 5. Increase process ribs. Some thin-walled workpieces are specially made with several process ribs at the clamping position to enhance the rigidity here, so that the clamping force acts on the process ribs to reduce the deformation of the workpiece. After the processing is completed, the process ribs are removed. .

- 6. When axial clamping fixtures should be used to turn thin-walled workpieces, radial clamping should not be used as much as possible, and the axial clamping method shown in Figure 4 is preferred. The workpiece is clamped axially by the end face of the axial clamping sleeve (threaded sleeve). Since the clamping force F is distributed along the axial direction of the workpiece, the axial rigidity of the workpiece is large, and it is not easy to produce clamping deformation.

Link to this article:The Solutions Of Deformation For CNC Turning Thin-Walled Parts

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:The Solutions Of Deformation For CNC Turning Thin-Walled Parts

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^