Researchers at the Skoltech Design, Manufacturing and Materials Center and their colleagues developed and experimentally verified a chaotically reinforced thermoplastic composite model of short glass fibers.

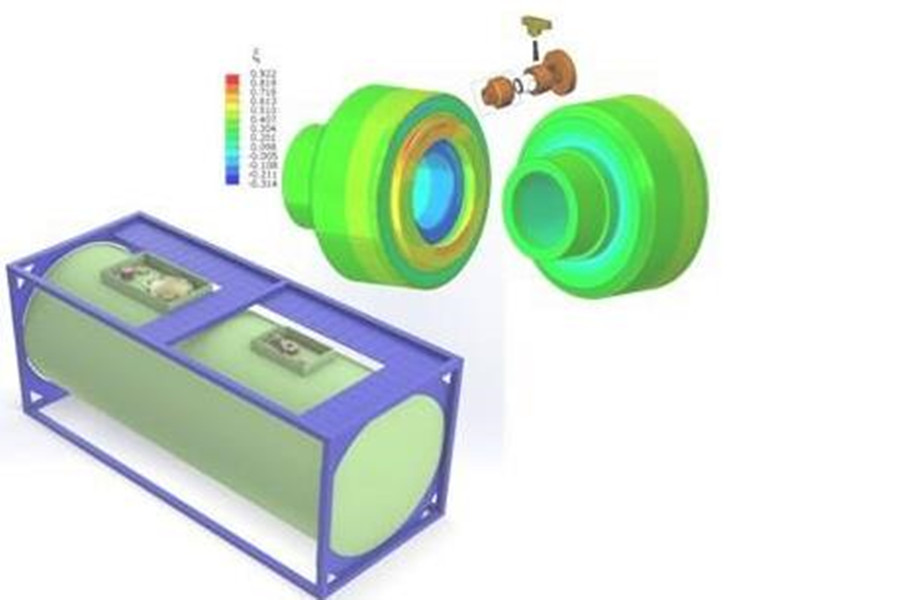

The validity and applicability of the model have been proven in the strength calculations of composite valves and safety devices for portable tanks used for the transportation of chemical substances on roads, railways and seas. The results were published in the International Journal of Pressure Vessels and Piping.

One of the most important scientific and engineering issues in promising structural design is the lack of proven mathematical models to describe the behavior of polymer composites in complex products. Together with scientists from the Department of Mechanics and Mathematics of Lomonosov Moscow State University, the Skoltech team was able to construct and verify such a model.

Compared with traditional materials such as steel, wood, and concrete, fiber reinforced plastic (FRP) structural members have obvious advantages and are widely used in civil engineering, shipbuilding and road construction. The FRP structure is manufactured using a pultrusion process in which the material is continuously pulled to achieve polymerization. Engineers extensively use mathematical models to optimize the pultrusion process, thereby avoiding expensive experiments that are often carried out through trial and error.

In order to optimize the pultrusion process, many parameters that determine the quality of the final product should be carefully considered, and the composition of the polymer mixture is one of them. An accurate description of pultrusion requires an appropriate model of resin curing kinetics, depending on the processing additives used. If selected properly, the model helps determine the highest possible pulling speed. In turn, maximizing the drawing speed while maintaining the quality of the final profile is essential to improve the efficiency and cost-effectiveness of the pultrusion process.

The developed model can significantly reduce the conservativeness of strength calculations in structural design and customization, which means minimizing subsequent manufacturing costs while meeting the necessary safety and quality requirements, Assistant Professor Ivan Sergeichev said.

The results obtained show that the mathematical model of composite behavior is suitable for “virtual testing” of structures, rather than expensive full-scale testing.

Our research team is under the support of the Russian Maritime Registry, and within the framework of the project experiment and digital certification platform of the Technet roadmap of the National Technology Initiative Program, the modeling method is introduced to confirm the compliance and certification of a highly responsible structure During the procedure, Ivan Sergeichev pointed out.

Link to this article:Mathematical model of thermoplastic composites

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Mathematical model of thermoplastic composites

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^