Scientists and engineers at Lawrence Livermore National Laboratory (LLNL) are 3D printing flow-through electrodes (FTE), a core component product used to convert CO 2 and other molecules into useful electrochemical reactors.

As described in a paper published in the Proceedings of the National Academy of Sciences, LLNL engineers 3D printed carbon FTE (the porous electrode responsible for the reaction in the reactor) from graphene aerogel for the first time. By taking advantage of the design freedom provided by 3D printing, the researchers demonstrated that they can customize the flow in the FTE and significantly improve mass transfer—liquid or gaseous reactants are transported through the electrodes to the reaction surface. The researchers said that this work opens the door to establishing 3D printing as a viable, universal rapid prototyping method for flow-through electrodes and a promising way to maximize reactor performance.

At LLNL, we are the first to use a three-dimensional reactor to precisely control the local reaction environment. The lead author of the paper and LLNL engineer Victor Beck said that the new high-performance electrode will become an important part of the next generation of electrochemical reactor architecture. This advancement demonstrates how we can use the control provided by the 3D printing function to the electrode structure to design local fluid flow and induce complex inertial flow patterns to improve reactor performance.

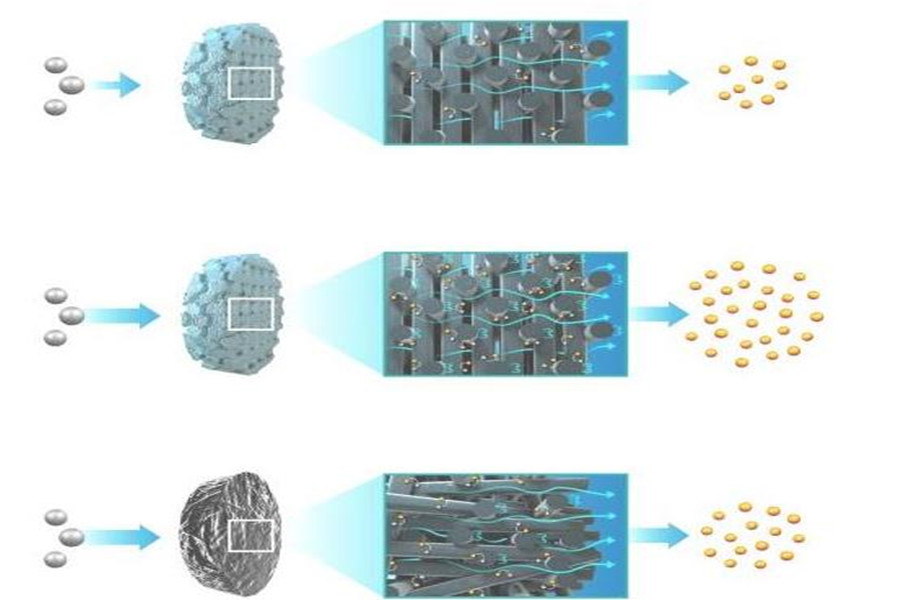

Through 3D printing, the researchers demonstrated that by controlling the electrode’s flow channel geometry, they can optimize the electrochemical reaction while minimizing the trade-offs in FTE manufactured by traditional methods. The typical materials used in FTE are “disordered” media, such as carbon fiber-based foam or felt, which limits the opportunities for designing its microstructure. The researchers explained that although production costs are low, randomly arranged materials are affected by uneven flow and mass transfer distribution.

By 3D printing advanced materials such as carbon aerogel, it is possible to design macroporous networks in these materials without affecting the physical properties such as conductivity and surface area, said co-author Swetha Chandrasekaran.

The team reported that the FTE printed in the lattice structure by the direct ink writing method has improved mass transfer by 1-2 orders of magnitude compared with the previously reported 3D printing work, and achieved performance comparable to traditional materials.

The researchers stated that since the commercial viability and widespread adoption of electrochemical reactors depend on obtaining greater mass transfer, the ability to design flows in FTE will make this technology a more attractive option to help solve the global energy crisis . Improving the performance and predictability of 3D printed electrodes also makes them suitable for use in amplified reactors for high-efficiency electrochemical converters.

Co-author Anna Ivanovskaya said that fine control of electrode geometry will enable advanced electrochemical reactor engineering that was not possible with the previous generation of electrode materials. Engineers will be able to design and manufacture structures optimized for specific processes. Potentially, with the development of manufacturing technology, 3D printed electrodes may replace traditional disordered electrodes for liquid and gas type reactors.

Scientists and engineers at LLNL are currently exploring the use of electrochemical reactors in a range of applications, including the conversion of CO 2 into useful fuels and polymers and electrochemical energy storage to further deploy electricity from carbon-free and renewable energy sources. The researchers said that promising results will enable them to quickly explore the impact of engineered electrode structures without the need for expensive industrial manufacturing techniques.

LLNL is working to produce more robust electrodes and reactor components at higher resolutions through light-based 3D polymer printing technologies (such as projection micro-stereolithography and two-photon lithography, flow through metallization). The team will also use high-performance computing to design better-performing structures, and continue to deploy 3D printed electrodes in larger and more complex reactors and full electrochemical cells.

Scientists and engineers at Lawrence Livermore National Laboratory (LLNL) are 3D printing flow-through electrodes (FTE), a core component product used to convert CO 2 and other molecules into useful electrochemical reactors.

As described in a paper published in the Proceedings of the National Academy of Sciences, LLNL engineers 3D printed carbon FTE (the porous electrode responsible for the reaction in the reactor) from graphene aerogel for the first time. By taking advantage of the design freedom provided by 3D printing, the researchers demonstrated that they can customize the flow in the FTE and significantly improve mass transfer—liquid or gaseous reactants are transported through the electrodes to the reaction surface. The researchers said that this work opens the door to establishing 3D printing as a viable, universal rapid prototyping method for flow-through electrodes and a promising way to maximize reactor performance.

At LLNL, we are the first to use a three-dimensional reactor to precisely control the local reaction environment. The lead author of the paper and LLNL engineer Victor Beck said that the new high-performance electrode will become an important part of the next generation of electrochemical reactor architecture. This advancement demonstrates how we can use the control provided by the 3D printing function to the electrode structure to design local fluid flow and induce complex inertial flow patterns to improve reactor performance.

Through 3D printing, the researchers demonstrated that by controlling the electrode’s flow channel geometry, they can optimize the electrochemical reaction while minimizing the trade-offs in FTE manufactured by traditional methods. The typical materials used in FTE are “disordered” media, such as carbon fiber-based foam or felt, which limits the opportunities for designing its microstructure. The researchers explained that although production costs are low, randomly arranged materials are affected by uneven flow and mass transfer distribution.

By 3D printing advanced materials such as carbon aerogel, it is possible to design macroporous networks in these materials without affecting the physical properties such as conductivity and surface area, said co-author Swetha Chandrasekaran.

The team reported that the FTE printed in the lattice structure by the direct ink writing method has improved mass transfer by 1-2 orders of magnitude compared with the previously reported 3D printing work, and achieved performance comparable to traditional materials.

The researchers stated that since the commercial viability and widespread adoption of electrochemical reactors depend on obtaining greater mass transfer, the ability to design flows in FTE will make this technology a more attractive option to help solve the global energy crisis . Improving the performance and predictability of 3D printed electrodes also makes them suitable for use in amplified reactors for high-efficiency electrochemical converters.

Co-author Anna Ivanovskaya said that fine control of electrode geometry will enable advanced electrochemical reactor engineering that was not possible with the previous generation of electrode materials. Engineers will be able to design and manufacture structures optimized for specific processes. Potentially, with the development of manufacturing technology, 3D printed electrodes may replace traditional disordered electrodes for liquid and gas type reactors.

Scientists and engineers at LLNL are currently exploring the use of electrochemical reactors in a range of applications, including the conversion of CO 2 into useful fuels and polymers and electrochemical energy storage to further deploy electricity from carbon-free and renewable energy sources. The researchers said that promising results will enable them to quickly explore the impact of engineered electrode structures without the need for expensive industrial manufacturing techniques.

LLNL is working to produce more robust electrodes and reactor components at higher resolutions through light-based 3D polymer printing technologies (such as projection micro-stereolithography and two-photon lithography, flow through metallization). The team will also use high-performance computing to design better-performing structures, and continue to deploy 3D printed electrodes in larger and more complex reactors and full electrochemical cells.

Link to this article: 3D printed flow electrodes open the door to maximize reactor performance

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:3D printed flow electrodes open the door to maximize reactor performance_PTJ Blog

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^