Novel Aviation Boosts tungsten and Molybdenum Consumption

- Details

- Category: Tungsten’s News

- Published on Thursday, 24 June 2021 21:42

The novel aviation materials would boost the tungsten (W) and molybdenum (Mo) market. In the 21st century, aircraft materials are directed to high performance, high functionality, multi-function, structure-function integration, intelligence, low cost, and compatibility with the environment. As one of the key materials for aircraft components, the consumption of W and Mo products is expected to increase.

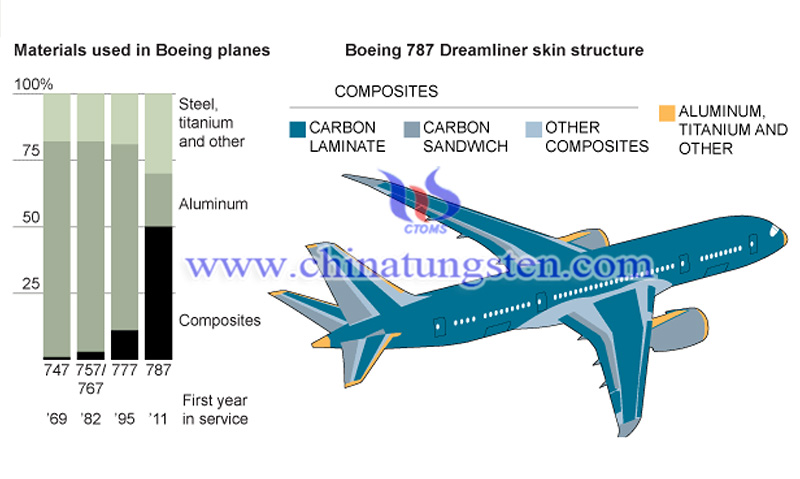

The high altitude, high speed, and high maneuverability of fighter jets require that the structural materials of the aircraft must ensure sufficient strength and rigidity performance, which means that the airframe material should have a greater ability to withstand effective loads. At present, titanium alloys and composite materials have gradually replaced steel and aluminum alloy materials as aircraft structures.

Moreover, the material of the fuselage should also have a small weight and good invisibility. The reduction in structural weight means that it can carry more fuel or other payloads, not only increase the flight distance, but also increase the cost-effectiveness of the unit structure weight. Therefore, compared with steel and aluminum alloys, titanium alloys and composite materials are more suitable for production Aircraft structure. In terms of stealth, the windows of aircraft can be made of tungsten trioxide (WO3) nano-powder.

WO3 is an important semiconductor material with excellent electrochromic and photochromic properties. Therefore, whether it is day or night, the light in the cabin will appear softer, and the scenery from the window will not be so dazzling.

High temperature resistance is the main development direction of this material. When the engine turbine inlet temperature is increased from 1300K to 1610K, the turbine output efficiency can be increased from 46.40% to 51.60%. This requires that engine materials should be upgraded and replaced with high-temperature alloys. In modern aviation engines, the amount of superalloys accounts for 40% to 60% of the total weight of the engine.

One of the ways to find the best heat-resistant alloy is to use a metal with a high melting point as the base of the alloy, such as Mo alloy. Although the melting point of Mo (2622°C) is lower than that of W (3410°C), it is more suitable for use in aero engines because the specific gravity of Mo is 10.22g/cm3 and the specific gravity of W is 19.3g/cm3.

Studies have shown that the high temperature resistance of molybdenum alloys is superior to that of nickel-based and cobalt-based alloys. In addition, Mo also has good thermal conductivity, which is more conducive to the manufacture of high-temperature parts. Because the combustion chambers, guides, turbine blades, and turbine disks in aero engines usually weather uneven heat and cold, if the thermal conductivity of the material does not reach the standard, the parts would be easily broken.

Besides, aircraft heat shields can also be made of W plates to prevent heat transfer; load-bearing components are sprayed with W carbide coating, which can prolong service life and improve reliability; The use of W alloy for the counterweight reduces the occurrence of safety accidents and improves transportation efficiency; tungsten and MoS2 for sliding parts effectively reduce the wear rate.

According to industry forecasts, there will be 40,664 aircraft delivered globally from 2020 to 2039, valued at approximately US$5.96 trillion. Among them, China is about to deliver 8725 new planes, that is, dual-aisle passenger planes accounted for 21.41%, a total of 1868; single-aisle passenger planes accounted for 68.05%, a total of 5937 planes; the remaining 10.54% will be 920 regional passenger planes. Therefore, the aviation industry would boost tungsten and molybdenum consumption.

- Next >

Link to this article:Novel Aviation Boosts Tungsten and Molybdenum Consumption

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Tungusten,Thanks!^^